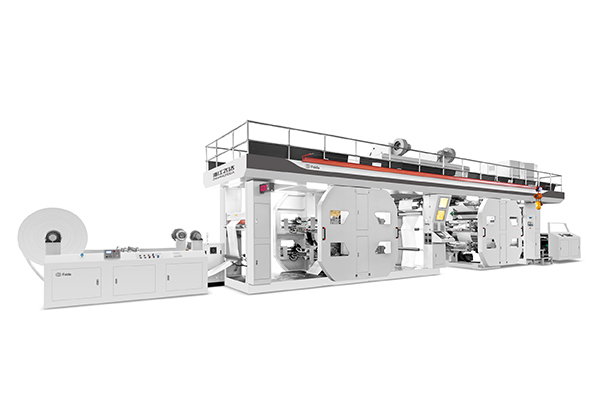

How CI Flexo Printing Machines Work: A Comprehensive Overview

CI Flexo (Central Impression Flexographic) printing machines are sophisticated devices used primarily in the packaging industry for high-quality, high-speed printing on various substrates. This article delves into the workings of CI Flexo printing machines, exploring their components, processes, and applications.

Components of a CI Flexo Printing Machine

-

Central Impression Drum: This is the central cylinder around which the substrate (typically a flexible material like plastic film or paper) travels during printing. It ensures consistent impression and registration accuracy.

-

Anilox Roll: This cylinder transfers ink from the ink pan to the printing plates. It has a textured surface engraved with tiny cells that meter precise amounts of ink onto the plates.

-

Printing Plates: These are flexible plates made of photopolymer or rubber, which carry the image or text to be printed. Multiple plates are mounted around the central impression drum.

-

Inking System: CI Flexo machines feature an ink pan or chamber where ink is stored. Doctor blades or other metering systems regulate the amount of ink transferred to the anilox roll and subsequently to the printing plates.

-

Substrate Handling System: The substrate (e.g., film or paper) is fed into the machine, guided around the impression drum, and then rewound or cut to size after printing.

-

Drying System: After the ink is applied to the substrate, it passes through a drying system that typically includes heaters or UV lamps to cure and set the ink quickly.

Operation of a CI Flexo Printing Machine

-

Setup: Operators mount the printing plates onto the central impression drum, aligning them precisely for registration. The anilox rolls are installed and calibrated to deliver the correct amount of ink.

-

Ink Application: The substrate is fed into the machine and guided around the impression drum. As it passes through the printing station, ink is transferred from the anilox roll to the printing plates. The plates then transfer the inked image onto the substrate.

-

Printing: The central impression drum rotates continuously, ensuring that each printing plate applies its designated color or part of the image onto the substrate in precise registration with the others.

-

Drying: Immediately after printing, the substrate passes through a drying system. Heat or UV light cures the ink, allowing it to adhere permanently to the substrate without smudging or smearing.

-

Finishing: Once dried, the printed substrate may undergo additional processes such as lamination, cutting, or folding depending on the specific requirements of the packaging or printing job.

Applications and Advantages

CI Flexo printing is widely used for various packaging applications including flexible packaging (bags, pouches), labels, corrugated cardboard, and more. Its advantages include:

- High-Speed Production: CI flexo printing machine can operate at very high speeds, making them ideal for large-volume runs.

- Excellent Print Quality: The combination of precise registration and controlled ink application results in sharp, vibrant prints.

- Versatility: These machines can handle a wide range of substrates and print designs, from simple text to complex, multi-color graphics.

Conclusion

In conclusion, CI Flexo printing machines are pivotal in modern packaging and label production industries due to their efficiency, speed, and print quality. Understanding their operation—from substrate feeding to ink application and drying—highlights their importance in meeting the demands of today's fast-paced manufacturing environments. As technology continues to advance, CI Flexo printing remains at the forefront, continuously improving to meet the ever-changing needs of the packaging industry.