How Many Types of Flexo Printing Machines are There?

There are six types of flexo printing machine commonly used in the printing industry.

Advantages and Disadvantages of Different Types of Flexo Printing Machines

The following is a summary of the advantages and disadvantages of different types of flexo printing press :

1. Center Press / CI Flexo Printing Machine

Pros: It has highly stable printing quality and is suitable for long printing operations; it can achieve high printing speed; it is suitable for printing large-area squeeze marks and solid color blocks.

Cons: It takes a long time to install and adjust the printing plate; printing density and color control may be difficult.

2. Stacking flexo printing machine

Pros: Each stacking unit can be set up and operated independently, with high flexibility; suitable for multi-color printing and special effects; changes in printing needs can be achieved by adding or deleting stacking units.

Cons: Large floor space; high requirements for tension adjustment and alignment control during the printing process.

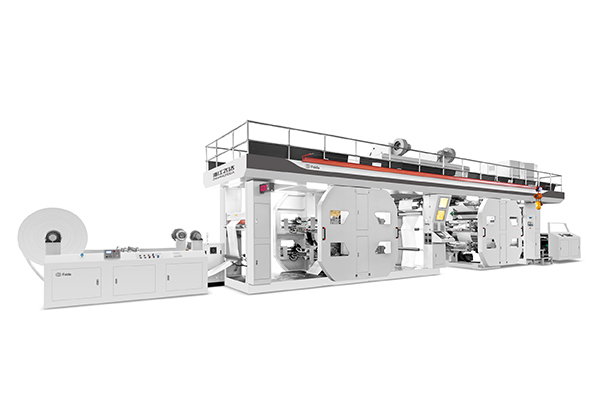

3. Inline flexo printing machine

Pros: Combining flexo printing with die-cutting, laminating, coating and other processes to achieve a continuous production process; saving time and cost in processing steps; suitable for high printing speed and multi-functional requirements.

Cons: The equipment is complex and maintenance and operation costs are high; the flexo printing part may be limited by other processes.

4. Modular flexo printing machine

Pros: It has interchangeable modules that can be customized according to needs; high flexibility, components such as printing units and drying systems can be added or removed according to different tasks and requirements.

Cons: higher cost; requires certain technical knowledge and experience to operate and adjust.

5. Sleeve type flexo printing machine

Pros: Use a sleeve made of flexible materials to install the printing plate, and replace the printing plate quickly; reducing work preparation time and downtime.

Cons: The quality and accuracy of the sleeve have a certain impact on the printing quality; suitable for relatively small printing sizes.

6. Label flexo printing machine

Pros: Designed specifically for label printing, with special features for handling narrow web stock and achieving high-quality label production.

Cons: only suitable for specific label printing needs, low versatility.