How To Tell A Bad Plate On Flex Printing

In flexographic printing, a "bad plate" can lead to poor-quality prints, resulting in defects such as smudging, color inconsistencies, and improper ink transfer. The main signs of a bad flexo plate include visible damage (e.g., cracks or scratches), improper exposure, and a lack of proper relief, which affects the image quality. A poorly exposed plate may also result in blurry or faded prints. Regular maintenance, proper storage, and correct plate processing are crucial to preventing bad plates and ensuring optimal print quality.

Key Signs of a Bad Plate in Flexographic Printing

1. Visible Physical Damage

Physical damage, such as cracks, tears, or scratches, can occur during handling, storage, or setup. These imperfections can interrupt the ink flow during printing, leading to inconsistent and flawed prints. Inspecting the plate carefully before use is essential to ensure that it remains in good condition.

2. Improper Exposure

Exposure time is critical when preparing flexographic plates. Overexposure can lead to excessive hardening of the plate, while underexposure can leave the plate too soft. Both conditions compromise the plate’s performance, resulting in poor ink transfer and inaccurate reproduction of the artwork. Correct exposure is necessary to ensure that the plate has the right level of hardness for the best image quality.

3. Lack of Proper Relief

A properly processed flexo plate has a raised image surface (relief) that receives ink for printing. If the plate is poorly processed, the relief may be inconsistent, causing gaps or uneven ink coverage. This can lead to a blurry or incomplete print, especially on detailed designs. Adequate processing of the plate during plate-making is essential to achieve high-quality prints.

4. Ink Transfer Issues

Inadequate ink transfer can be a direct result of poor plate quality. A bad plate may not pick up the correct amount of ink, leading to faded colors or incomplete prints. It's essential to monitor ink transfer throughout the printing run and replace the plate if necessary.

Preventing Bad Plates in Flexographic Printing

To minimize the risk of bad plates, it's important to use high-quality materials, perform regular maintenance on the equipment, and follow precise plate-making procedures. Proper handling and storage of plates are also critical to avoiding physical damage. By maintaining strict quality control in the pre-press and plate-making stages, printers can ensure consistent, high-quality results in their flexographic printing operations.

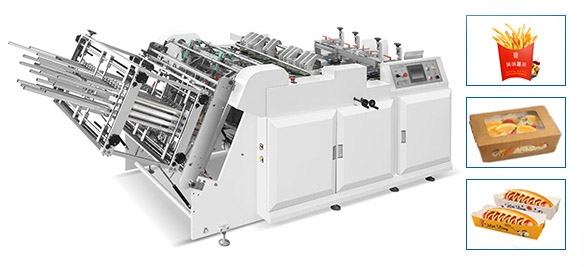

The Role of the Feida Flexo Printing Machine

The Feida flexo printing machine offers significant advantages in flexographic printing, providing solutions for a variety of printing needs. It supports single- and double-sided printing and can perform offset and gravure printing simultaneously, making it a versatile choice for diverse projects. The machine is equipped with automatic functions such as paper feeding, high-speed positioning, automatic metering, and drying, which contribute to increased production efficiency and enhanced print quality.

With its advanced features, the Feida flexo printing machine ensures consistent, high-quality results, even when working with complex designs or various printing materials. This technology minimizes the risk of errors caused by bad plates, helping to maintain smooth operations and reduce waste. By automating key steps in the printing process, the Feida flexo printing machine enables faster, more efficient production, making it an essential tool for businesses looking to improve their flexographic printing capabilities.