What are the advantages of Roll Die Cutting Machine?

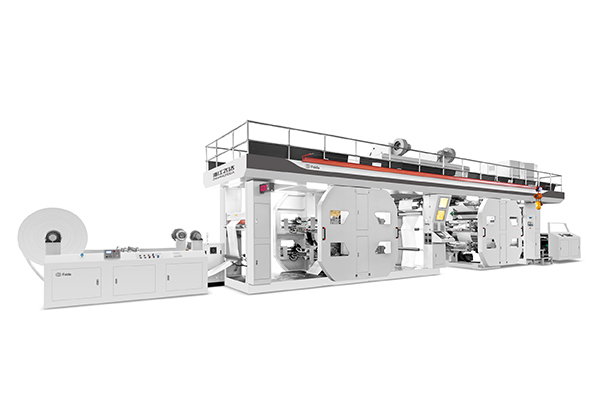

Roll Die Cutting Machine is an advanced printing equipment widely used in the paper packaging industry. It uses advanced computer control technology to cut a large number of roll materials such as paper, tape, plastic film, etc. into various shapes of labels, tags, bags, etc.

The advantages of Roll Die Cutting Machine?

High precision and high quality: The roll die cutting machine adopts a precise cutting mechanism and automatic peeling function to ensure that each cut is flawless, avoiding the uneven edges and inaccuracies common in traditional die cutting methods. In addition, the machine also has high stability and high safety, and is able to produce high-quality products.

Energy-saving: The roll die cutting machine is designed to minimize waste during the cutting process and is equipped with a waste removal system such as a waste removal mechanism or a vacuum system to effectively remove excess material and separate it from the finished product. This energy-saving design not only improves production efficiency, but also reduces resource waste.

Versatility: The roll die cutting machine can not only perform die cutting, but also creasing and embossing, and is suitable for various PE coated paper, ordinary paper, corrugated paper and plastic materials. This versatility makes the roll die-cutting machine widely used in a variety of environmentally friendly products such as paper cups, cartons, medical packaging, wine packaging, food packaging, etc.

High degree of automation: roll die-cutting machines are usually equipped with microcomputers, human-machine interface control, servo positioning, AC inverters, and automatic counting.

Wide range of applications: roll die-cutting machines are suitable for a variety of materials and product types, including paper cups, cartons, medical packaging, wine packaging, food packaging, and other environmentally friendly products. Its wide range of applications makes it an ideal choice for the paper packaging industry.

Choosing the right roll die cutting machine depends entirely on your operational needs and the specific functions you require. Different machines offer varying capabilities, so it's crucial to prioritize what matters most to your production process.

Here are some of the primary functions you can find in die cutting machines:

1. Through Cutting: This is the fundamental function of die cutters, where the machine cuts completely through the material, separating the design from the stock.

2. Kiss Cutting: Used primarily for adhesive-backed materials like labels and stickers, kiss cutting cuts through the top layers (face and adhesive) without separating the die-cut part from the backing material, allowing for easy detachment.

3. Perforating: This function involves creating a series of holes in the material, making it easily tearable while keeping the design connected to the stock. Perforations are useful for items like tear-off coupons or packaging that requires easy opening.

4. Scoring: Scoring creates a partial cut or indent at a single stress point, typically used for materials that need to be folded neatly, like cards or boxes. It reduces the material thickness to facilitate folding without fully separating it.

5. Creasing: Similar to scoring but with a distinct difference: creasing creates a fold line with an inward bulge between two stress points. This technique ensures the material can hold its shape after folding, commonly used in packaging and card making.

To optimize your die cutting operations:

Choose Wisely: Select a machine that aligns with your specific production requirements, considering factors such as material type, volume, and desired speed.

Train Your Team: Proper training for operators ensures they can effectively use, troubleshoot, and maintain the machine, minimizing downtime and maximizing productivity.

Consult Experts: If you're uncertain about which machine suits your needs best, seek guidance from professionals like Feida Machinery. They offer a range of advanced die cutters and packaging equipment, tailored to various production demands.

By understanding these functions and optimizing your equipment choice and operational practices, you can leverage your die cutting machine to enhance productivity and meet your manufacturing goals effectively.