What is anilox in flexo printing?

Understanding Anilox in Flexo Printing: The Heart of Precision and Consistency

Flexographic printing, commonly referred to as flexo printing, is a versatile and widely used printing technique known for its ability to produce high-quality prints on a variety of substrates, including paper, plastic, and film. At the core of this printing process lies a critical component known as the anilox roll. This seemingly simple yet highly engineered tool plays a pivotal role in ensuring the precision, consistency, and efficiency of flexo printing. In this article, we will explore what an anilox roll is, how it functions, and why it is indispensable in the flexo printing process.

What is an Anilox Roll?

The anilox roll is a cylinder, typically made of steel, aluminum, or ceramic, that is engraved with millions of tiny cells or recesses. These cells are responsible for transferring a controlled amount of ink from the ink chamber to the printing plate. The roll's surface is often coated with a ceramic layer to enhance durability and resistance to wear, especially when abrasive inks are used.

The design and specifications of an anilox roll, such as the number of cells per linear inch (referred to as the line screen) and the volume of the cells (measured in billion cubic microns or BCM), are tailored to the specific requirements of the print job. These parameters determine how much ink is transferred, which directly affects the print quality, color consistency, and overall efficiency of the process.

How Does an Anilox Roll Work?

The anilox roll operates as part of the inking system in a flexo press. Here’s a step-by-step breakdown of its role:

1. Ink Application: The anilox roll rotates through the ink fountain or chamber, where its cells pick up a precise amount of ink.

2. Excess Ink Removal: A doctor blade scrapes off any excess ink from the surface of the roll, leaving only the ink trapped within the cells.

3. Ink Transfer: The roll then comes into contact with the flexographic printing plate, transferring the ink from the cells to the raised areas of the plate.

4. Printing: Finally, the plate transfers the ink onto the substrate, creating the desired image or text.

This process ensures that the ink application is consistent, which is crucial for achieving uniform print quality, especially in high-speed production runs.

Key Factors in Anilox Roll Selection

Selecting the right anilox roll is critical to achieving optimal print results. Here are the key factors to consider:

1. Line Screen (LPI): The number of cells per linear inch determines the resolution of the print. Higher LPI rolls are used for fine details, while lower LPI rolls are suitable for solid areas and heavy ink coverage.

2. Cell Volume (BCM): The volume of the cells dictates how much ink is transferred. A higher BCM is ideal for vibrant colors and opaque prints, while a lower BCM is better for fine details and lighter tones.

3. Cell Shape and Geometry: The shape of the cells (e.g., hexagonal, pyramidal, or helical) affects ink release and transfer efficiency. Hexagonal cells are the most common due to their optimal balance of ink capacity and release.

4. Material and Coating: Ceramic-coated rolls are preferred for their durability and resistance to wear, especially in high-volume or abrasive ink applications.

The Importance of Anilox Rolls in Flexo Printing

The anilox roll is often referred to as the heart of the flexo printing process, and for good reason. Its role in controlling ink transfer directly impacts:

Print Quality: Consistent ink application ensures sharp, vibrant, and accurate prints.

Color Consistency: Precise ink control minimizes variations in color, which is critical for brand consistency.

Efficiency: Properly selected anilox rolls reduce ink waste and downtime, improving overall productivity.

Versatility: By choosing the right anilox roll, printers can adapt to different substrates, ink types, and design requirements.

Maintenance and Care of Anilox Rolls

To ensure the longevity and performance of anilox rolls, proper maintenance is essential. This includes:

a.Regular cleaning to remove dried ink and debris from the cells.

b.Using appropriate cleaning solutions and tools to avoid damaging the roll’s surface.

c.Storing rolls in a controlled environment to prevent corrosion or physical damage.

d.Periodic inspection to identify and address any wear or damage.

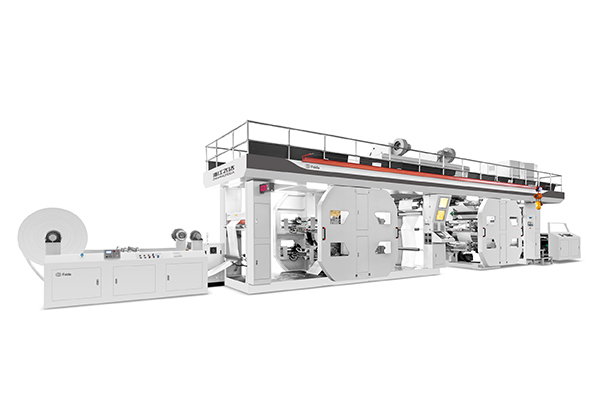

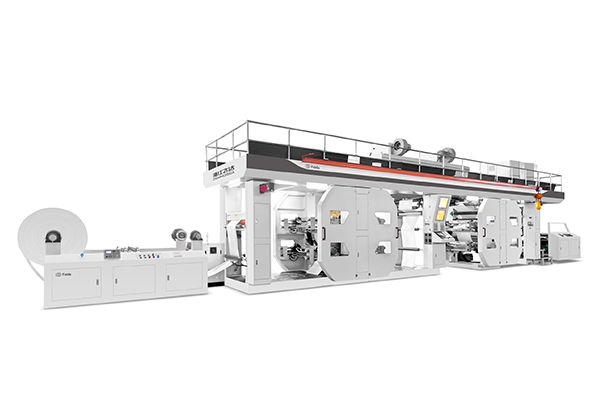

Customize your own flexographic printing press from Feida

Feida CI Flexo Printing Machine The printing part of the flexographic printing press consists of ink rollers, ceramic anilox rollers, printing rollers, and support rollers. It can complete a variety of printing operations such as single-sided and double-sided printing, offset printing, and gravure printing at the same time. It can be applied to a variety of printing materials and has paper feeding, automatic metering, high-speed positioning, drying, automatic shutdown and other functions, which greatly improves production efficiency and printing quality.

We recognize that every business has unique needs, Printing color group: 1 color-10 colors to meet different customer needs so we provide fully customizable configurations to ensure that our machines fully meet your operational goals and specifications. Whether you are engaged in packaging, printing, processing or manufacturing, Feida can provide precision and reliability, enabling your business to achieve optimal performance and productivity through machines designed specifically for your process.

Conclusion

The anilox roll is a cornerstone of flexo printing, enabling the precise and consistent transfer of ink that defines the quality of the final product. Its design, selection, and maintenance are critical to achieving optimal print results and maximizing the efficiency of the printing process. As flexo printing continues to evolve with advancements in technology and materials, the anilox roll remains an indispensable tool, ensuring that this versatile printing method meets the ever-growing demands of the industry.

Whether you’re a seasoned printer or new to the world of flexography, understanding the role and importance of the anilox roll is key to unlocking the full potential of this dynamic printing technique.