What is Flexography Printing Most Commonly Used for?

Flexographic printing, also known as flexographic printing, is most commonly used for the high-volume production of packaging materials, particularly on flexible substrates such as plastic and cardboard.

Flexographic printing is particularly suitable for printing on uneven or rough surfaces, including corrugated cardboard, paper bags, plastic bags and food packaging.

What is a flexo printing machine?

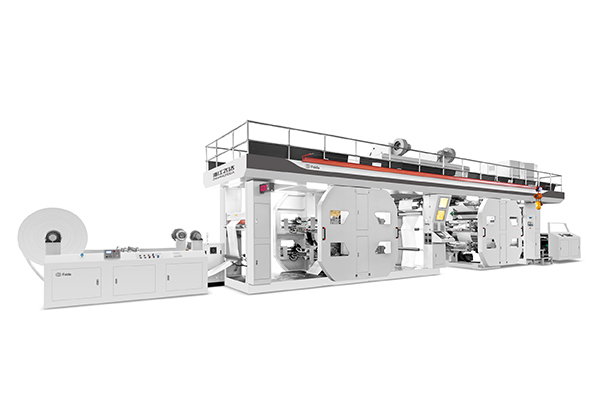

A flexo printing machine is a device used to perform flexographic printing.

Through flexo printing machines, large-scale, high-efficiency flexographic printing production can be achieved to meet the needs of various industries for packaging materials.

What are the characteristics of flexo printing machines?

Flexo printing machines have some important features, such as:

(1) Quickly adjust printing settings

(2) Adapt to high-speed production

(3) Printing quality is stable

Flexo printing machines can achieve high-resolution printing effects and are suitable for different types of paper and plastic films.

In what industries is flexographic printing commonly used?

1. Packaging industry

Flexo printing is widely used for printing on labels, cartons, boxes, bags, shrink wrap and other forms of packaging.

2. Food and Beverage Industry

Flexo printing can be used to print packaging for food and beverage products, such as plastic bottles, laminated foils and paper bags.

3. Pharmaceutical industry

Flexo printing is commonly used for printing on medical packaging, including prescription labels, blister packs and folding cartons.

4. Textile industry

Flexo printing can be used to print patterns on fabrics, clothing labels, and other textile products.

5. Industrial fabrics

Flexo printing can also be used to print designs on industrial fabrics, such as mesh screens and conveyor belts.

Overall

Flexo printing is a versatile printing method ideal for high-volume production of high-quality, cost-effective packaging products.