What is the Difference between Flexo and Gravure Printing?

When choosing a printing method, it is crucial to understand the advantages and disadvantages of different technologies.

This article will compare Flexo Printing and Gravure Printing, and analyze their respective advantages and disadvantages.

Flexographic printing:

What are the advantages of flexo printing?

1. Versatility

Flexo printing can be used on a variety of substrates, including paper, plastic and metallic films.

2. Cost-effective

Compared to other printing methods, flexo printing is relatively inexpensive and suitable for mass production.

3. Fast production speed

Flexo presses can run at high speeds, reducing turnaround time for printing projects.

4. Good quality

Flexo printing delivers high-quality results with sharp images and vibrant colors.

5. Environmental protection

Flexo printing uses water-based or UV-curable inks, which are more environmentally friendly than solvent-based inks.

What are the disadvantages of flexo printing?

1. Limited resolution

Due to the nature of the printing process, flexo printing can have limitations in achieving fine details and small text.

2. Plate making complexity

Making plates for flexo printing can be more complex and time-consuming than other methods.

3. Ink drying time

Flexo inks can take longer to dry, which can slow down the production process.

4. Limited color options

Flexo printing can have limitations in reproducing multiple colors, especially when compared to digital printing methods.

5. Substrate limitations

Certain substrates, such as uneven or highly absorbent materials, may not be suitable for flexographic printing.

Gravure printing:

What are the advantages of gravure printing?

1. High image quality

Gravure printing provides excellent image reproduction with excellent detail and smooth gradations.

2. Consistent Ink Coverage

Gravure printing provides even and consistent ink coverage, resulting in high-quality prints.

3. Mass printing

Gravure printing is ideal for high-volume printing and is ideal for mass production.

4. Wide color gamut

Gravure printing can reproduce a wide range of colors, including vibrant metallic shades.

5. Long printing plate life

Gravure printing plates have a longer lifespan than other types of printing plates.

What are the disadvantages of gravure printing?

1. High setup cost

Gravure printing requires a large initial investment due to the complex machinery and plate-making process involved.

2. Limited selection of substrates

Gravure printing is mainly suitable for non-porous substrates such as plastics and metal foils, which limits its versatility.

3. Long setup time

Preparing gravure cylinders and adjusting presses for printing can be time-consuming, resulting in long setup times.

4. Environmental issues

Gravure printing typically uses solvent-based inks, which can have an environmental impact if not managed properly.

5. The flexibility of design changes is poor

Gravure printing offers less flexibility for design changes during the printing process than digital printing methods.

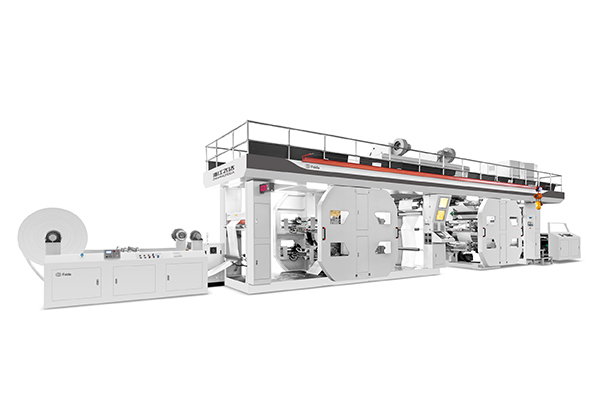

How to choose flexo printing or gravure printing machine?

Flexo is favored for its versatility and affordability, but can have limitations in terms of detail and drying time.

Gravure printing is superior in terms of image quality and ink coverage, but equipment investment and environmental concerns may be considerations.

Flexo printing machine are widely available and affordable, but can have limitations in terms of detail and drying time.

In comparison, gravure printing is superior in image quality and ink coverage, but equipment investment and environmental issues may need to be considered.

By understanding these differences, you can make a more informed choice about the method that suits your printing needs.