What is the Purpose of a Flexo Printing Machine?

The purpose of a flexo printing machine is to print high-quality images and designs on various flexible substrates, such as paper, cardboard, plastic films, and labels. Flexo printing, short for flexographic printing, is a popular printing technique that uses flexible printing plates and a rotary press to transfer ink onto the substrate.

What is the process of flexo printing machine?

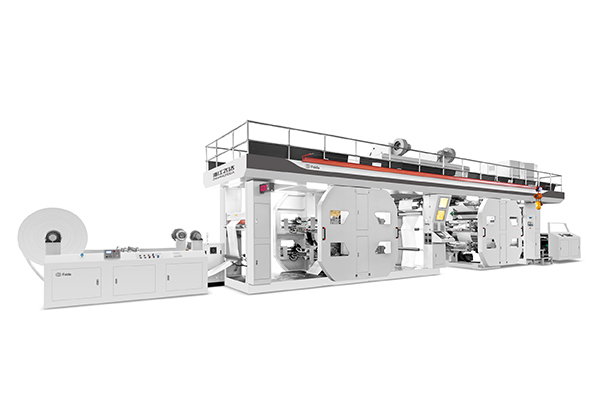

The flexo printing machine consists of several key components, including a plate cylinder, an anilox roller, an ink fountain, a doctor blade, and a printing cylinder.

1. The process begins by mounting the flexible printing plates onto the plate cylinder, which then rotates and transfers ink from the ink fountain to the anilox roller.

2. The anilox roller, with its engraved cells, meters and transfers a precise amount of ink to the printing plate.

3. The inked plate comes into contact with the substrate on the printing cylinder, creating the desired image or design.

Why choose flexo printing machine?

Flexo printing machines offer several advantages, including high printing speeds, excellent color reproduction, and the ability to print on a wide range of substrates.

Application field of flexo printing machine

Flexo printing machines are commonly used in industries such as packaging, label printing, flexible packaging, corrugated board printing, and more. The flexibility and versatility of flexo printing machines make them suitable for producing various products, including food packaging, labels, newspapers, magazines, and flexible plastic bags.

Overall

The purpose of a flexo printing machine is to provide a reliable and efficient printing solution for producing high-quality printed materials on flexible substrates.